SAMSON US offers a wide range of unique features and solutions that make US the largest spreader on the market with very high capacity, application precision and versatility.

The SpreadMaster 8500 gives you full control over the machine and its functions. The control ensures consistent dosing and optimal utilization of the nutrients in the material. Combining the control system with load cells allows extremely precise dosing for even better utilization of the nutrients in the material. SpreadMaster 8500 also enables dosing and documentation in relation to allocation cards as well as static and dynamic weighing.

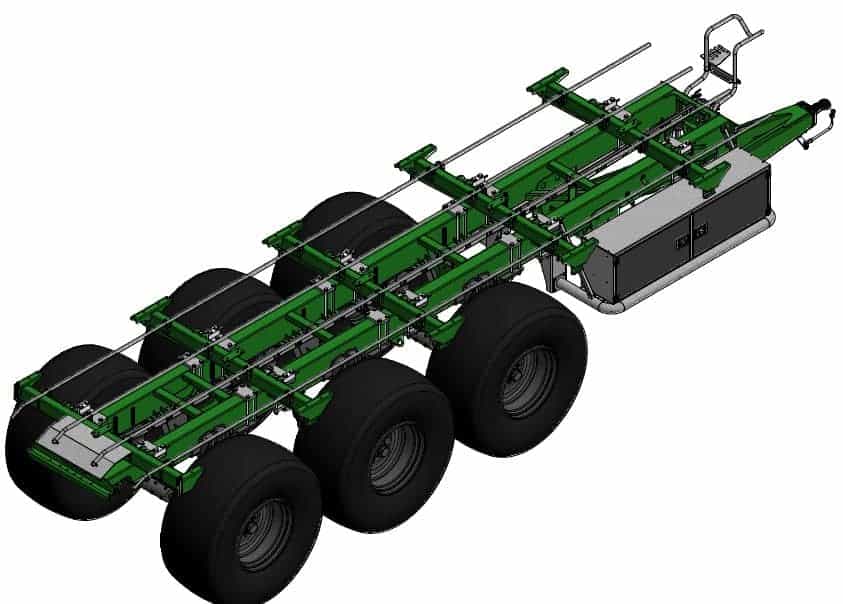

The SAMSON US series is available in a 2- and a 3-axle variant, US 2 and US 3. US 2 in 3 volume sizes from approximately 23 to 35 cubic meters. US 3 in 3 volume sizes from approximately 28 to 40 cubic meters.

To ensure optimum utilization of the dispersed material, shredding is a crucial factor. Efficient shredding contributes to faster decomposition of organic matter in the soil, which benefits plant growth and well-being. This is especially important for materials such as heavy cow dung or horse manure with a lot of straw. SAMSON US meets this need by using three specially developed ripper rollers that ensure efficient shredding of the spreading material.

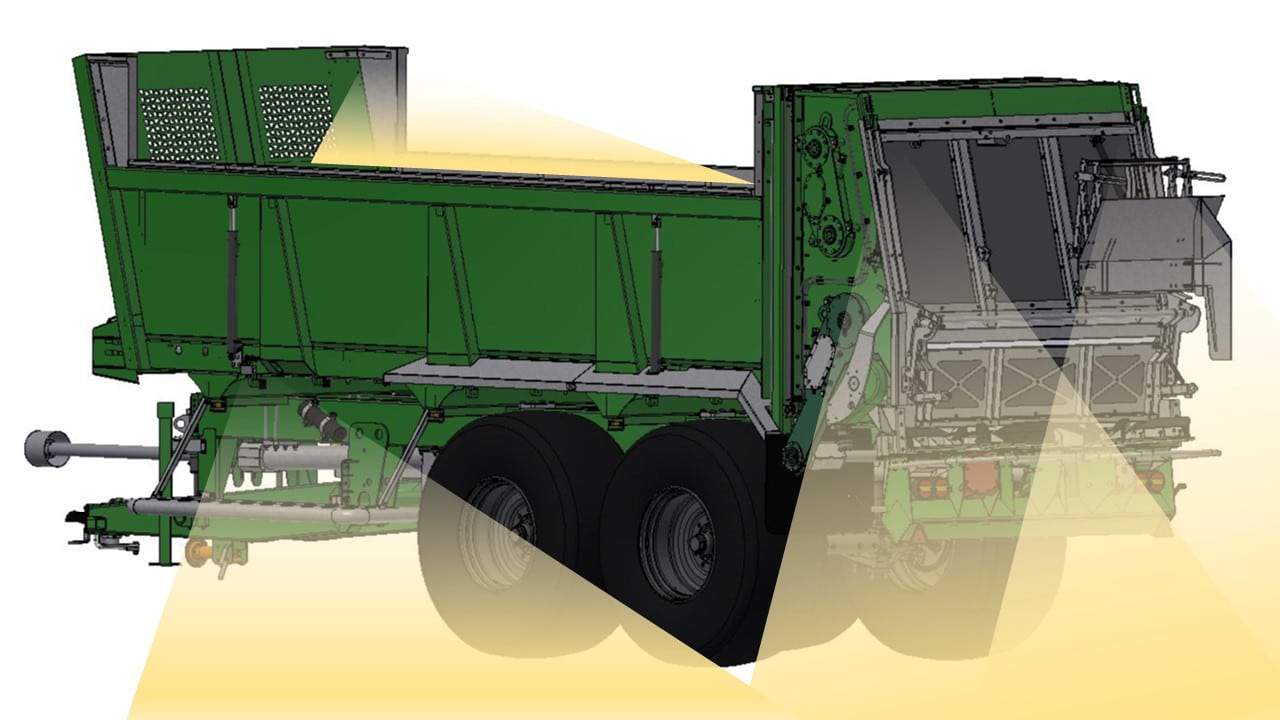

The spreading pattern plays a crucial role for optimal utilization of the spreading material, especially when it comes to nutrient-rich materials such as poultry manure, compost or lime. Correct dosing is essential to avoid both under- and overdosing, as both can result in lower yields and lower profits. That’s why SAMSON US is equipped with many adjustment options that allow you to achieve the optimal spread pattern.

SAMSON US is equipped with three horizontal ripper rollers designed to ensure a reliable and efficient spreading process. The roller spikes, supported at the rear as on other SAMSON spreaders, minimize the risk of spike loss during operation. The rollers are driven by chain gears running in a closed oil bath, ensuring minimal maintenance and reliable operation over time. The side gears are also equipped with safety clutches to protect the gearboxes from damage in case of large foreign objects in the rollers.

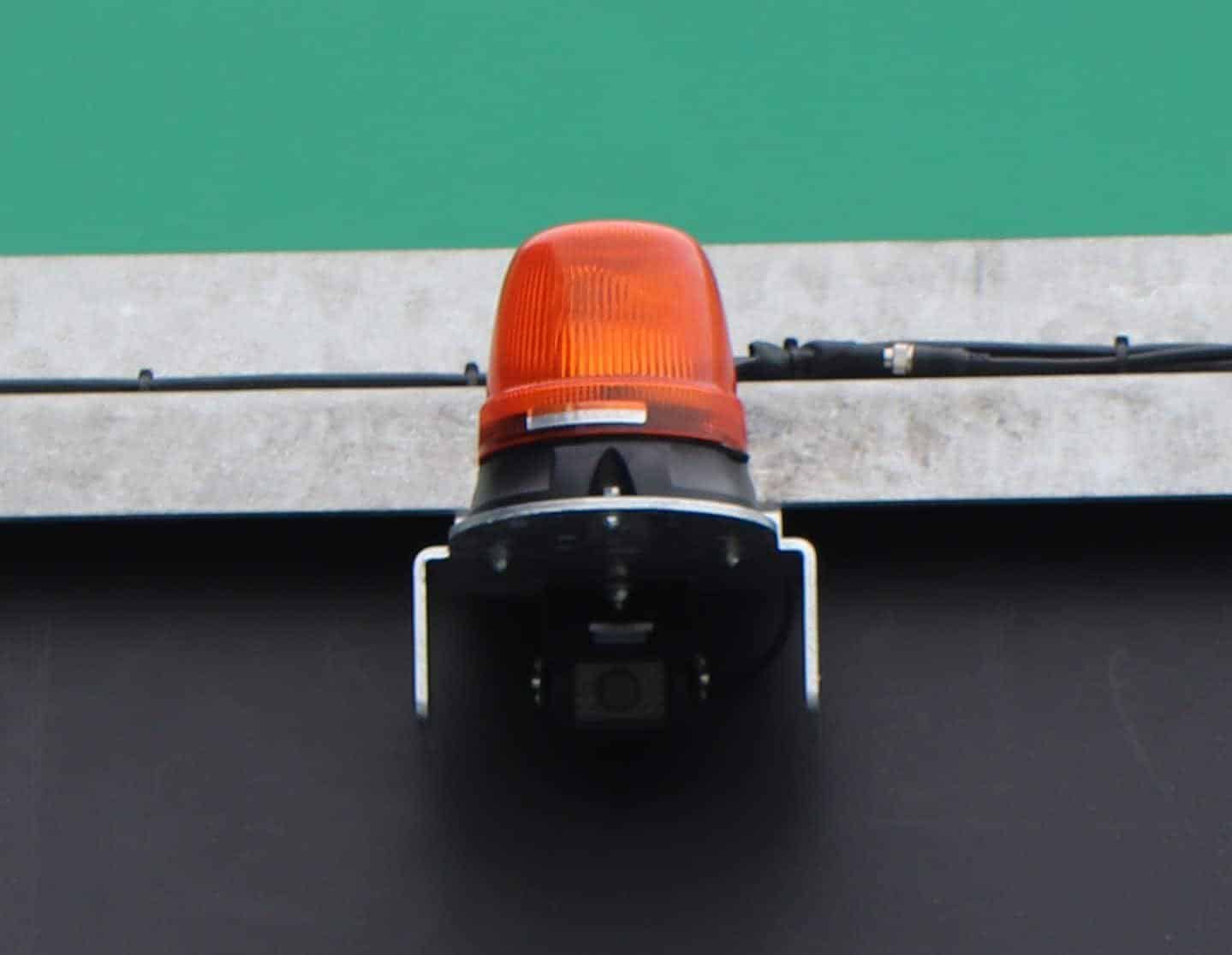

SAMSON US is also available with load cells that enable precise dosing and documentation of spreading material quantity and location. This not only ensures accurate dosing, but also provides valuable documentation of the farmer’s work.

To ensure optimum utilization of the dispersed material, shredding is a crucial factor. Efficient shredding contributes to faster decomposition of organic matter in the soil, which benefits plant growth and well-being. This is especially important for materials such as heavy cow dung or horse manure with a lot of straw. SAMSON US meets this need by using three specially developed ripper rollers that ensure efficient shredding of the spreading material.

The spreading pattern plays a crucial role for optimal utilization of the spreading material, especially when it comes to nutrient-rich materials such as poultry manure, compost or lime. Correct dosing is essential to avoid both under- and overdosing, as both can result in lower yields and lower profits. That’s why SAMSON US is equipped with many adjustment options that allow you to achieve the optimal spread pattern.

SAMSON US is equipped with three horizontal ripper rollers designed to ensure a reliable and efficient spreading process. The roller spikes, supported at the rear as on other SAMSON spreaders, minimize the risk of spike loss during operation. The rollers are driven by chain gears running in a closed oil bath, ensuring minimal maintenance and reliable operation over time. The side gears are also equipped with safety clutches to protect the gearboxes from damage in case of large foreign objects in the rollers.

SAMSON US is also available with load cells that enable precise dosing and documentation of spreading material quantity and location. This not only ensures accurate dosing, but also provides valuable documentation of the farmer’s work.

Samson is a leader in the production of spreaders designed to optimize application efficiency and maximize the utilization of nature’s own nutrients.

We offer a comprehensive range of spreaders, tools and technologies, all tailored to meet the needs of the agricultural industry.

Our goal is to provide innovative and environmentally friendly solutions for efficient spreading of organic fertilizers, where every step of the process is carefully thought out. With our spreaders, farmers can make optimal use of resources while contributing to sustainable farming practices.

Monday – Thursday:

07.00 – 16.00

Friday

07.00 – 15.00

Petersmindevej 6, DK-8800 Viborg

VAT no. 10963230

Copyright © 2024 Samson Agrolize