The SAMSON TSB range is designed to provide an efficient SAMSON TSB, a wise investment solution that meets your needs. Several working widths and equipment options are available.

Because you demand the best, we’ve been testing our booms in demanding conditions for years. The result? It applies organic fertilizer precisely and evenly in all soil types. In short, the SAMSON TSB series is characterized by its

ALSIDIGHED.

From grassland to stubble fields, grain and other crops, our skidding boom is a winner in any field. Its unique design and ability to follow the contours of the soil provides a unique and sustainable application of organic fertilizer in hilly terrain.

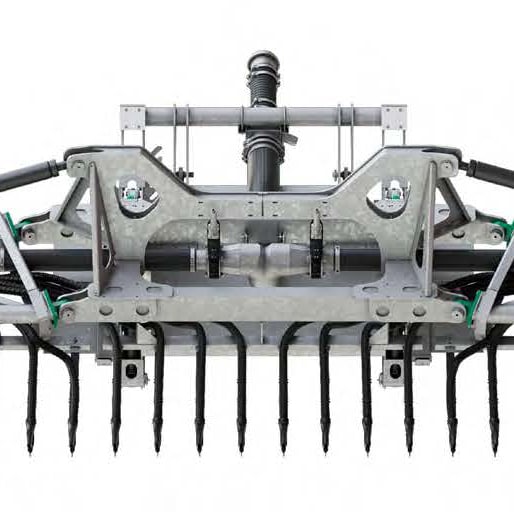

A unique, patented design ensures optimal performance and durability, while a wear indicator clearly informs the operator when the center wear part needs replacing – a task that can easily be completed in under a minute. The center wear part works consistently to maintain even ground pressure throughout its lifetime.

The special shape of the slurry nozzle improves the slurry outlet, ensuring even distribution even under maximum capacity, resulting in high precision. The SAMSON skid system is designed to overcome all types of terrain and obstacles, providing impressive flexibility.

A distance of 25 cm between the skid shoes ensures an even distribution across. Hoses with a diameter of 43 mm are extremely flexible and follow the movements of the machine without overloading. The smooth inner surface optimizes flow and the specially developed black SAMSON hoses are highly resistant to UV radiation.

Our SAMSON vertical distributor has maintained a standard of distribution that is unrivaled over the years. It has proven its reliability and high performance with any type of slurry, even the most demanding types.

Depending on the dosage, our SAMSON manifold can be adapted to the specific capacity needs. Its unique design ensures an even distribution of natural fertilizer, increasing nutrient levels and maximizing yields.

We created SAMSONS vertical distributors to be robust and reliable. Their design ensures constant operation and prevents unnecessary downtime. Whatever the conditions, our benefits ensure a smooth workflow and reduced maintenance costs. Your productivity is our top priority.

A unique, patented design ensures optimal performance and durability, while a wear indicator clearly informs the operator when the center wear part needs replacing – a task that can easily be completed in under a minute. The center wear part works consistently to maintain even ground pressure throughout its lifetime.

The special shape of the slurry nozzle improves the slurry outlet, ensuring even distribution even under maximum capacity, resulting in high precision. The SAMSON skid system is designed to overcome all types of terrain and obstacles, providing impressive flexibility.

A distance of 25 cm between the skid shoes ensures an even distribution across. Hoses with a diameter of 43 mm are extremely flexible and follow the movements of the machine without overloading. The smooth inner surface optimizes flow and the specially developed black SAMSON hoses are highly resistant to UV radiation.

Our SAMSON vertical distributor has maintained a standard of distribution that is unrivaled over the years. It has proven its reliability and high performance with any type of slurry, even the most demanding types.

Depending on the dosage, our SAMSON manifold can be adapted to the specific capacity needs. Its unique design ensures an even distribution of natural fertilizer, increasing nutrient levels and maximizing yields.

We created SAMSONS vertical distributors to be robust and reliable. Their design ensures constant operation and prevents unnecessary downtime. Whatever the conditions, our benefits ensure a smooth workflow and reduced maintenance costs. Your productivity is our top priority.

You no longer have to face the dilemma between maximizing productivity and maintaining precision in your farming. Our revolutionary SAMSON TSB skid steer booms have demonstrated their unmatched performance and value in the field. We are committed to continuous improvement and innovation, resulting in the development of state-of-the-art solutions that meet your ever-increasing demands on farming practices. By working with you, we focus not only on delivering efficient tools, but also on creating sustainable solutions that reduce the environmental impact of agricultural activities.

Monday – Thursday:

07.00 – 16.00

Friday

07.00 – 15.00

Petersmindevej 6, DK-8800 Viborg

VAT no. 10963230

Copyright © 2024 Samson Agrolize