TS single cut traps are designed to achieve optimal utilization of the manure’s fertilizer value in multiple crop types and soil conditions. The Incorporator is available in two widths, 8 or 12 meters. The two models are called TS 8 and TS 12 respectively.

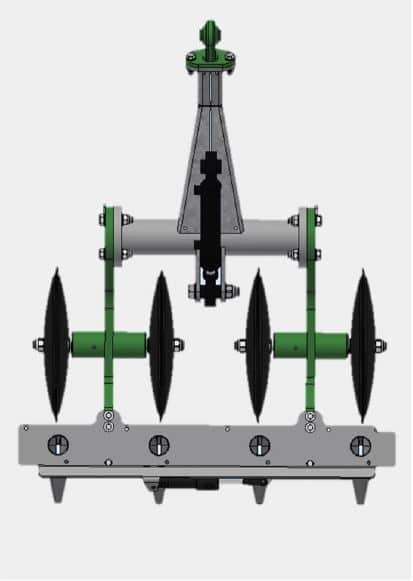

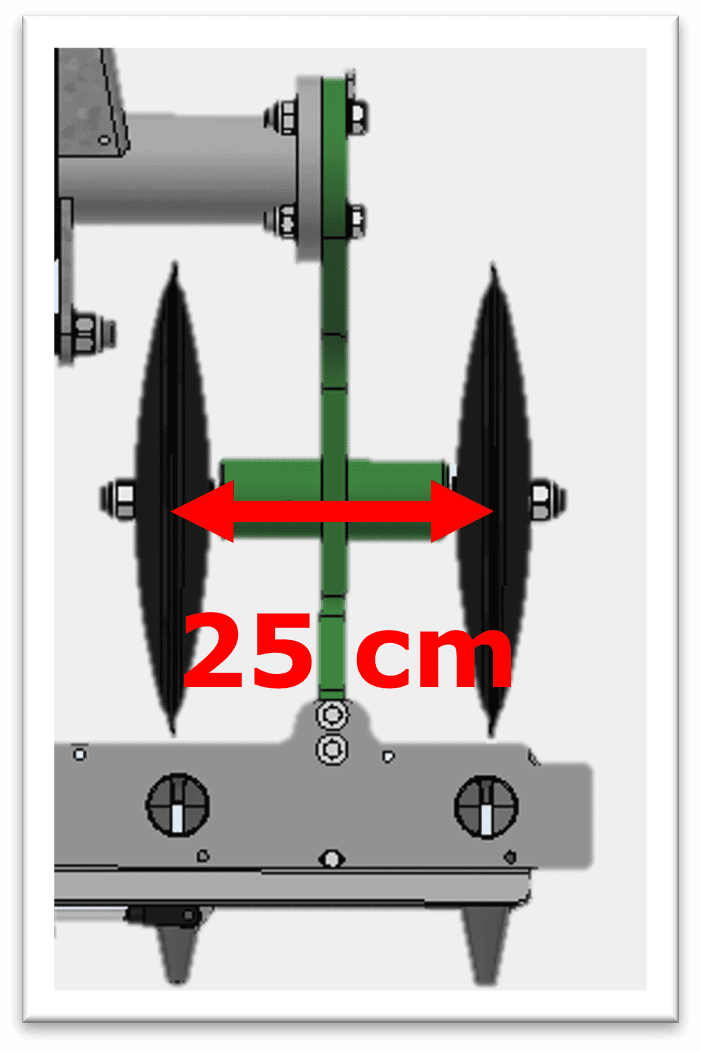

The TS is built in sections, which together with the depth control ensures a uniform working depth when placing slurry in the grooves created by the single coulters. The sections are 1 meter wide and there are 8 or 12 individual cutting sections, each mounted on the main frame with a pivoting point. This gives the fall arrester more flexibility when cornering as well as in hilly terrain. Each section has four single blades with minimal maintenance and precise individual ADS (anti-drip stop) functionality that minimizes start/stop time to a minimum, resulting in high application precision.

The Incorporator has a relatively low weight of 2,650 and 3,400 kg due to the high-quality and strong materials chosen and is equipped with the well-known SAMSON distributor with high capacity and strong wear parts.

The ISOBUS-compatible SAMSON Section Control (TC-SC) allows farmers to implement advanced section control of their implements using GPS positioning. This feature automates the control of the implements, minimizing overlapping and overdosing of slurry, especially in complex terrains such as wedges. This precision is not only beneficial to the environment by reducing unnecessary pollution, but it also increases crop yield potential by ensuring a more efficient use of fertilizer.

The Section Control function is particularly suitable for SAMSON SHB4 dragline booms where it can control up to four sections, but it can also handle up to two sections on other attachments. This flexibility allows farmers to adapt their section control to different farming operations and terrain conditions, contributing to increased productivity and resource efficiency.

The ISOBUS “Variable Rate” functionality allows farmers to optimize their fertilization strategy using automated processes in collaboration with an ISOBUS-compatible GPS system. This advanced approach to fertilizer application relies on data from yield maps from previous years or NDVI vegetation indices, typically collected through satellite or drone imagery.

By analyzing this data, farmers can create application maps that precisely control the amount of fertilizer applied via the tractor’s GPS system and the SAMSON control system. This technology enables a more precise and tailored application of nutrients to the fields, which not only increases yields but also reduces the risk of local over-fertilization and environmental impact. Variable dosage technology thus contributes to both economic benefits and a more sustainable operating model in modern agriculture.

The ISOBUS-compatible SAMSON Section Control (TC-SC) allows farmers to implement advanced section control of their implements using GPS positioning. This feature automates the control of the implements, minimizing overlapping and overdosing of slurry, especially in complex terrains such as wedges. This precision is not only beneficial to the environment by reducing unnecessary pollution, but it also increases crop yield potential by ensuring a more efficient use of fertilizer.

The Section Control function is particularly suitable for SAMSON SHB4 dragline booms where it can control up to four sections, but it can also handle up to two sections on other attachments. This flexibility allows farmers to adapt their section control to different farming operations and terrain conditions, contributing to increased productivity and resource efficiency.

The ISOBUS “Variable Rate” functionality allows farmers to optimize their fertilization strategy using automated processes in collaboration with an ISOBUS-compatible GPS system. This advanced approach to fertilizer application relies on data from yield maps from previous years or NDVI vegetation indices, typically collected through satellite or drone imagery.

By analyzing this data, farmers can create application maps that precisely control the amount of fertilizer applied via the tractor’s GPS system and the SAMSON control system. This technology enables a more precise and tailored application of nutrients to the fields, which not only increases yields but also reduces the risk of local over-fertilization and environmental impact. Variable dosage technology thus contributes to both economic benefits and a more sustainable operating model in modern agriculture.

SAMSON is a leader in the production of traps designed to optimize application efficiency and maximize the utilization of nature’s own nutrients.

We offer a comprehensive range of harvesting machines, attachments and technologies, all tailored to meet the needs of the agricultural industry.

Our goal is to provide innovative and environmentally friendly solutions for efficient manure deposition, where every step of the process is carefully considered. With our traps, farmers can make optimal use of resources while contributing to sustainable farming practices.

Monday – Thursday:

07.00 – 16.00

Friday

07.00 – 15.00

Petersmindevej 6, DK-8800 Viborg

VAT no. 10963230

Copyright © 2024 Samson Agrolize