The Strip-Till slurry spreader is designed for early placement of slurry for row crops. The fall arrester is available with 8 rows.

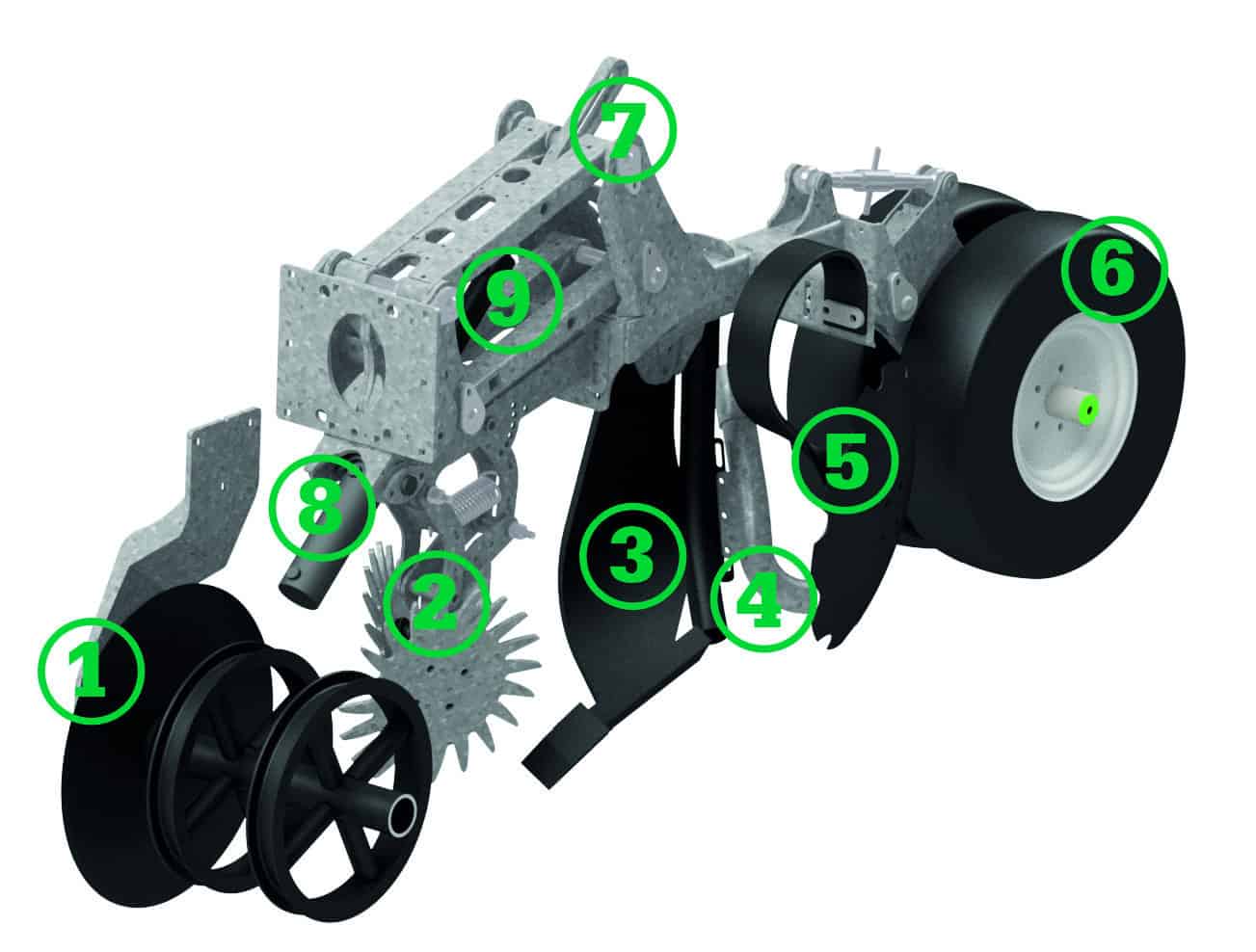

The function is the same, the Strip-Till’s front drum with cutter first cuts a groove. The two cleaning wheels effectively remove plant material in the tillage area and the unique parabolic cutterbar lifts the soil and creates a V-shaped opening in the ground with plenty of space for the slurry. The slurry nozzles place the slurry in two strings. The disc then smoothes and closes the ground surface again and the packing wheels leave a fine surface.

The precise placement of slurry not only reduces the use of mineral starter fertilizer for corn, but also gives you an effective tool to comply with new phosphorus regulations and maintain high yields.

SAMSON Strip-Till is available in two versions – 6 and 8 rows. The function is the same, the Strip-Till’s front drum with cutter first cuts a groove. The two cleaning wheels effectively remove plant material in the tillage area and the unique parabolic cutterbar lifts the soil and creates a V-shaped opening in the ground with plenty of space for the slurry.

The slurry nozzles place the slurry in two strings. The disc then smoothes and closes the ground surface again and the packing wheels leave a fine surface.

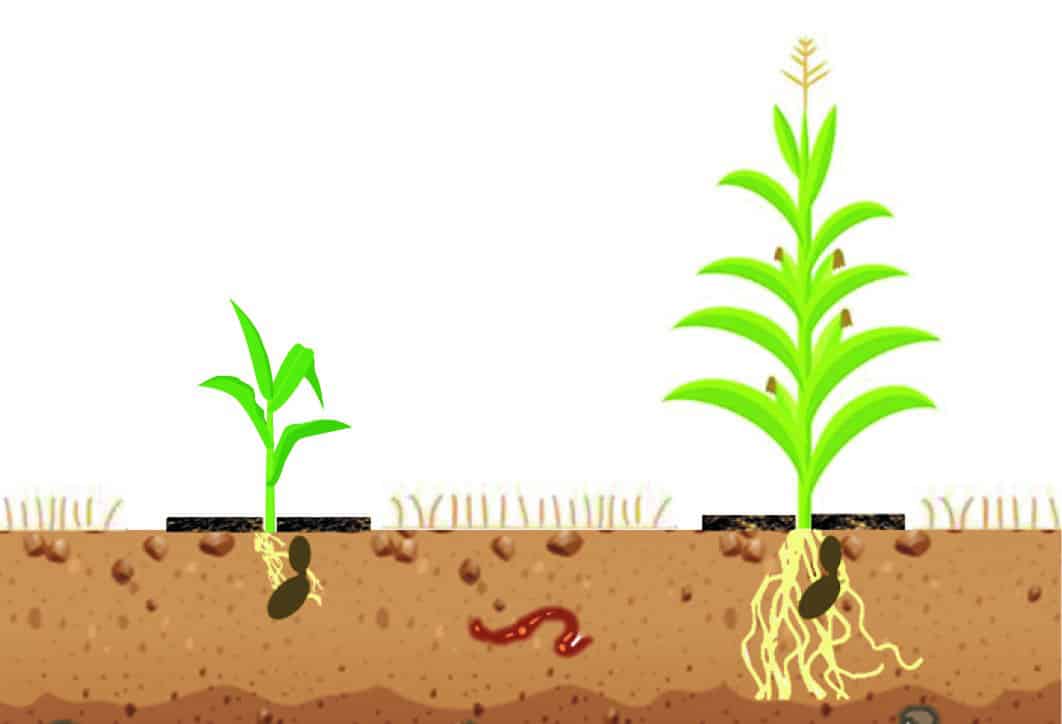

SAMSON Strip-Tills workflow is functional and very precise. The slurry is placed in two strings:

1: approx. 30% in the upper and 2: approx. 70% in the lower slurry line. The width of the tillage area is 25-30 cm, working depth 20-30 cm, 75 cm between rows is standard but can be adjusted.

The distance between crop and slurry is approximately 5-7 cm. The precise placement of the slurry using SAMSON Strip-Till ensures high utilization of nutrients in the slurry throughout the growing season.

SAMSON is a leader in the production of traps designed to optimize application efficiency and maximize the utilization of nature’s own nutrients.

We offer a comprehensive range of harvesting machines, attachments and technologies, all tailored to meet the needs of the agricultural industry.

Our goal is to provide innovative and environmentally friendly solutions for efficient manure deposition, where every step of the process is carefully considered. With our traps, farmers can make optimal use of resources while contributing to sustainable farming practices.

Monday – Thursday:

07.00 – 16.00

Friday

07.00 – 15.00

Petersmindevej 6, DK-8800 Viborg

VAT no. 10963230

Copyright © 2024 Samson Agrolize