The SP series is the most widely used of our spreaders. It is the result of 65 years of SAMSON know-how and we have continuously developed and adapted the SP series for intensive agricultural use.

With the SP spreaders, we were the first manufacturer in the world to launch spreading equipment with vertical rollers, which significantly increased capacity. The SP Series’ most important feature is its ability to easily, precisely and efficiently distribute and spread manure evenly on the field. This is essential for the plants to utilize the fertilizer.

The SP series is highly versatile and geared to handle all kinds of spreading tasks. This is an absolutely reliable spreader series with very low maintenance costs. There are six sizes; 9, 11, 12, 14, 15 and 17 cubic meters.

The SAMSON SP is equipped with manual bottom chain control as standard, but can be upgraded to MuckControl or SpreadMaster 6500

MuckControl is an electronic bottom chain control. With MuckControl, the operator can regulate the speed of the bottom chain using a potentiometer. Spreading is started and stopped manually using an easy, simple, manually operated button.

SpreadMaster 6500 is an electronic control with drive dependency. SpreadMaster 6500 can control hydraulic functions and run volumetric dosing. The SpreadMaster 6500 controller has a 4.3″ touchscreen with all important functions on the main screen.

SpreadMaster 6500 continuously counts load, area, time and quantity together SpreadMaster 6500, the bottom chain speed runs proportional to the driving speed of the spreader. It ensures more precise dosing of the material and it counts spreading time, theoretical weight and number of hectares. Automatic volumetric dosing

The SpreadMaster 6500 control system offers automatic volumetric dosing. The principle is known from lime and fertilizer spreaders. The system adjusts the speed of the bottom chain according to the height of the dispensing shutter,

the driving speed and the set application rate per hectare. This allows for very accurate dosing especially in homogeneous, high-value materials such as poultry manure, compost or lime.

The SAMSON SP is equipped with manual bottom chain control as standard, but can be upgraded to MuckControl or SpreadMaster 6500

MuckControl is an electronic bottom chain control. With MuckControl, the operator can regulate the speed of the bottom chain using a potentiometer. Spreading is started and stopped manually using an easy, simple, manually operated button.

SpreadMaster 6500 is an electronic control with drive dependency. SpreadMaster 6500 can control hydraulic functions and run volumetric dosing. The SpreadMaster 6500 controller has a 4.3″ touchscreen with all important functions on the main screen.

SpreadMaster 6500 continuously counts load, area, time and quantity together SpreadMaster 6500, the bottom chain speed runs proportional to the driving speed of the spreader. It ensures more precise dosing of the material and it counts spreading time, theoretical weight and number of hectares. Automatic volumetric dosing

The SpreadMaster 6500 control system offers automatic volumetric dosing. The principle is known from lime and fertilizer spreaders. The system adjusts the speed of the bottom chain according to the height of the dispensing shutter,

the driving speed and the set application rate per hectare. This allows for very accurate dosing especially in homogeneous, high-value materials such as poultry manure, compost or lime.

SP SERIES

Long lifetime

Proven and robust construction

The traction triangle is suspended with maintenance-free shock absorbers.

The SP series is constructed from high-strength steel

The spikes on the rollers are made of hardened steel

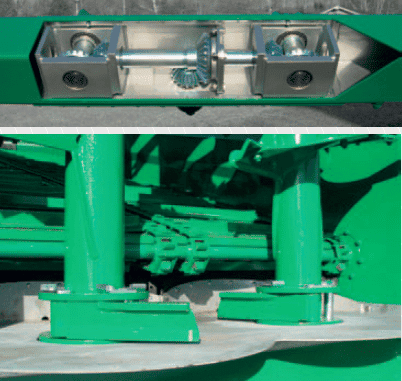

Unique triple SAMSON block gearbox with integrated flexible couplings

Several SP spreaders on the market have been in use for more than 20 years

Two double bottom chains with carriers for regular supply to the spreading equipment, dual direction rotation and low maintenance costs

High quality surface treatment - double layer polyurethane

Extremely efficient

Stable construction with low center of gravity

Low loading height for fast loading and increased productivity

Big wheels - less need for traction

Faster driving and faster earning

Roller spikes and angles: Proven design

Optimal diameter and rotation speed of the rollers

Optimal spread

Unrivaled performance

Can spread all types of materials

Tapered length design on the box for natural material feeding

Double vertical SAMSON rollers

Roller and spike design ensures optimal grinding, dosing and spreading of the material

Optimal spreading pattern for optimal utilization of manure

Robust gearbox: performance from 4 tons to 70 tons per hectare

Safety during transportation and no spillage on the road when driving with aqueous material by selecting the hydraulic dosing code

Low fuel consumption

Low tare weight - less need for traction

Larger wheels provide better weight transfer to the tractor and reduce rolling resistance

Proven technology and know-how

SAMSON has more than 65 years of experience spreading livestock manure

SAMSON is the first in the world to equip its SP spreaders with double vertical rollers

Samson is a leader in the production of spreaders designed to optimize application efficiency and maximize the utilization of nature’s own nutrients.

We offer a comprehensive range of spreaders, tools and technologies, all tailored to meet the needs of the agricultural industry.

Our goal is to provide innovative and environmentally friendly solutions for efficient spreading of organic fertilizers, where every step of the process is carefully thought out. With our spreaders, farmers can make optimal use of resources while contributing to sustainable farming practices.

Monday – Thursday:

07.00 – 16.00

Friday

07.00 – 15.00

Petersmindevej 6, DK-8800 Viborg

VAT no. 10963230

Copyright © 2024 Samson Agrolize