SD II is a further development of the popular SD slurry trap. With SD II, the descender has become lighter, the pressure point moved and several other parameters improved.

Designed for optimal slurry deposition in fields with a lot of plant material, the SD II slurry precipitator is not just a modified disc harrow for tillage.

For example, the slurry nozzles are located behind the front row of plates. The slurry is then placed in grooves created by the plates on the front row of plates. The rear row of plates instantly covers the grooves with soil. This minimizes evaporation. The Incorporator is available in three widths: 5, 6 and 7 meters.

The SD II precipitator is also characterized by the fact that the slurry is placed directly in the ground and not swirled with the material flow through the precipitator. It therefore works with relatively dry material and stays clean and dry. This minimizes problems with moisture ingress in bearings and joints, extending their lifetime.

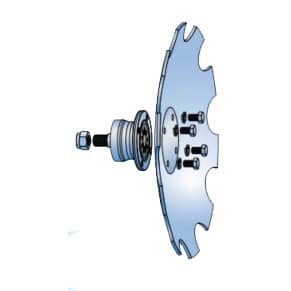

The 510 mm diameter serrated discs work aggressively and ground-seeking even in tough conditions. The design of the plate means that large amounts of plant material can be easily incorporated when spreading slurry. As slurry application and tillage can be done in a single pass, it allows you to reduce the number of passes over the field and thus reduce field management costs.

All plates are individually suspended on the frame via elastic rubber elements. This achieves maximum adaptation to the ground surface as each plate can follow the contour. This ensures that grooves and other recesses are also machined. An uneven ground surface will be evenly worked. The elastic rubber elements on each disc suspension not only ensure optimal adaptation to the ground contour, but also act as overload protection when driving on rocky ground. The large working area of the rubber elements allows the plate to deviate when in contact with large stones. The fact that the discs are simply suspended without a through shaft also allows large amounts of plant material to pass through the machine.

One of the most notable features of the SD II is the use of mono-suspension discs equipped with integrated slurry nozzles. This design feature is essential to ensure the best material flow through the machine.

Having slurry nozzles integrated directly into the plates offers several advantages. Firstly, the shock load on both discs and bearings is significantly reduced, extending the lifetime of the machine and reducing the need for maintenance. This reduction in impact load is particularly valuable in longer operating conditions where wear can become a concern.

In addition, the integrated slurry nozzle ensures that the slurry liquid is used with optimal efficiency during the depositing process. The slurry nozzle closely follows the movements of the disc, which means that the depositing is smooth and precise, even in uneven terrain or at varying speeds. This results in a more even distribution of the slurry liquid across the field, maximizing the absorption capacity of the crops and thus potentially increasing yields.

The 510 mm diameter serrated discs work aggressively and ground-seeking even in tough conditions. The design of the plate means that large amounts of plant material can be easily incorporated when spreading slurry. As slurry application and tillage can be done in a single pass, it allows you to reduce the number of passes over the field and thus reduce field management costs.

All plates are individually suspended on the frame via elastic rubber elements. This achieves maximum adaptation to the ground surface as each plate can follow the contour. This ensures that grooves and other recesses are also machined. An uneven ground surface will be evenly worked.

The elastic rubber elements on each disc suspension not only ensure optimal adaptation to the ground contour, but also act as overload protection when driving on rocky ground. The large working area of the rubber elements allows the plate to deviate when in contact with large stones. The fact that the discs are simply suspended without a through shaft also allows large amounts of plant material to pass through the machine.

One of the most notable features of the SD II is the use of mono-suspension discs equipped with integrated slurry nozzles. This design feature is essential to ensure the best material flow through the machine.

Having slurry nozzles integrated directly into the plates offers several advantages. Firstly, the shock load on both discs and bearings is significantly reduced, extending the lifetime of the machine and reducing the need for maintenance. This reduction in impact load is particularly valuable in longer operating conditions where wear can become a concern.

In addition, the integrated slurry nozzle ensures that the slurry liquid is used with optimal efficiency during the depositing process. The slurry nozzle closely follows the movements of the disc, which means that the depositing is smooth and precise, even in uneven terrain or at varying speeds. This results in a more even distribution of the slurry liquid across the field, maximizing the absorption capacity of the crops and thus potentially increasing yields.

SAMSON is a leader in the production of traps designed to optimize application efficiency and maximize the utilization of nature’s own nutrients.

We offer a comprehensive range of harvesting machines, attachments and technologies, all tailored to meet the needs of the agricultural industry.

Our goal is to provide innovative and environmentally friendly solutions for efficient manure deposition, where every step of the process is carefully considered. With our traps, farmers can make optimal use of resources while contributing to sustainable farming practices.

Monday – Thursday:

07.00 – 16.00

Friday

07.00 – 15.00

Petersmindevej 6, DK-8800 Viborg

VAT no. 10963230

Copyright © 2024 Samson Agrolize