SAMSON PG II Genesis sets a new standard in natural fertilizer application.

The machine’s extended tool-carrying capabilities give you the freedom to choose the right tool for the job. Application is intelligently controlled with the SlurryMaster 8000, which, together with the model’s robust high-capacity pump and built-in flow control system, ensures that slurry is dosed and placed efficiently and precisely for the benefit of the crop, the farmer’s yield and our shared environment.

An extension of the the hydraulic functionality of the SAMSON slurry tanker creates a machine with Maximum agility, delivery accuracy and comfort. Furthermore, the model is designed for the largest possible low-pressure tires and for optimal utilization of automatic wheel traction and tire pressure solutions that actively protect the crop and soil fertility.

SAMSON PG II Genesis is designed for efficient and precise slurry application.

The machine comes with technologies and features that set new standards for the application of natural fertilizers.

The SAMSON ejector system is a unique and patented ejector-vacuum pumping system that can pump even the most demanding liquids.

The system has a performance of up to 6000 liters per minute in water at a lifting height of 1 meter. The vacuum down to -0.9 bar is only created in the ejector pipe system and not in the entire tank of the slurry tanker. This keeps the weight of the slurry tanker to a minimum and ensures a fast vacuum reaction time and thus a quick start-up of filling.

The system contains no mechanical pump elements, which minimizes maintenance costs.

The SAMSON ejector system uses a small amount of slurry that is retained in the reservoir at the front of the slurry tanker. The slurry in the reservoir helps ensure good weight transfer to the tractor. If the ejector is not used, the restraint can be disengaged and the total volume of the slurry tanker is used during operation.

The pump tower is telescopic with two extensions and end-mounted filling pump. Two movable joints provide great flexibility and make the pump tower very easy and quick to operate.

There is the option of an optional work light and camera, which contributes to better visibility and relieves the operator for good ergonomics during operation.

In addition, the pump tower can be equipped with automatic return functionality to ensure fast and accurate parking after filling.

The most flexible solution where the robust ejector pump is combined with the pump tower.

The SAMSON ejector system is a unique and patented ejector-vacuum pumping system that can pump even the most demanding liquids.

The system has a performance of up to 6000 liters per minute in water at a lifting height of 1 meter. The vacuum down to -0.9 bar is only created in the ejector pipe system and not in the entire tank of the slurry tanker. This keeps the weight of the slurry tanker to a minimum and ensures a fast vacuum reaction time and thus a quick start-up of filling.

The system contains no mechanical pump elements, which minimizes maintenance costs.

The SAMSON ejector system uses a small amount of slurry that is retained in the reservoir at the front of the slurry tanker. The slurry in the reservoir helps ensure good weight transfer to the tractor. If the ejector is not used, the restraint can be disengaged and the total volume of the slurry tanker is used during operation.

The pump tower is telescopic with two extensions and end-mounted filling pump. Two movable joints provide great flexibility and make the pump tower very easy and quick to operate.

There is the option of an optional work light and camera, which contributes to better visibility and relieves the operator for good ergonomics during operation.

In addition, the pump tower can be equipped with automatic return functionality to ensure fast and accurate parking after filling.

The most flexible solution where the robust ejector pump is combined with the pump tower.

The system is an easy-to-operate system with an intuitive and clear user interface that ensures safe operation of the slurry tanker. The system is a standalone system developed solely to operate a slurry tanker, and therefore no compromises have been made in terms of choosing a standard platform to fit many different machines. The system is an extension of the well-known SlurryMaster 6000 control system.

All viewing/setting is done on a high-resolution 10″ color touchscreen. A lot of focus has been placed on the driver having to press a minimal number of times to navigate around. The display is based on standard PC technology. This future-proofs the investment as it is easy to adapt the system to tomorrow’s requirements.

It is possible to have up to 10 different attachment settings. Each tool can be named and set as needed. The first time a tool is mounted, run through the setup list. This saves the setting and can be used the next time you need to use the tool. This reduces the number of settings when changing tools.

The essential functions used to operate filling systems and tools are controlled from a newly developed and ergonomically designed joystick. The surface of the joystick is coated with silicone. All buttons are backlit and provide a distinctive clicking sensation when in use. There is a resting surface for the hand and a firm grip on the buttons to ensure safe operation even when driving on uneven surfaces.

A single tap on the joystick icon at the top of the screen brings up an overview of which functions are available at that time. The system is designed so that only the functions that the machine is equipped with are displayed at any given time.

The system can accommodate up to 18 jobs and 1 season counter. During each job, data is logged that can later form the basis for invoicing the customer. Customer name, driver name, field number and so on can be entered. When the job is finished, it can be saved to a USB stick in Excel format or printed. This can be used to create a customer database or all kinds of statistics.

The system is equipped with several tools that make it very easy to service and troubleshoot. Among other things, there is an error log that makes it easier to locate periodic errors. This means your authorized technician can find the fault faster and get the machine up and running again.

PG II GENESIS SERIES

Long lifespan - Strong construction

The tank is made of 5mm steel

Continuous vanes

The wheel brackets are made of Domex 600 high-strength steel

Fully welded chassis

Specially designed splash plates in the three compartments of the slurry tank ensure stability even with smaller loads

Cushioned, adjustable traction triangle absorbs shocks and jerks

The wheels are placed on the side of the tank - the result is a low center of gravity. The low center of gravity makes the structure more stable, so it is exposed to less stress. It extends the life of the trolley

Can transport heavy tools such as snake booms, grass and black soil harvesters

Minimal corrosion - strong surface both inside and out. Treated with epoxy on the inside

SAMSON Ejector suction system and SAMSON long-life loader pumps

High-capacity centrifugal unloading pump

High efficiency - High stability - faster driving and more loads per hour

The wheels are located on the side of the tank - the result is a low center of gravity that allows you to drive faster on the road and in the field

Large wheels, diameter up to 195 cm (depending on model), reduce rolling resistance

Hydraulic suspension system - stable ride

Specially developed unloading pump with high unloading capacity

Comes with SM 80 ball hitch as standard

Efficient work machine

Possible to use wide tools such as snake booms, grass and black soil traps

Heavy-duty tool carrier with high capacity and lift height

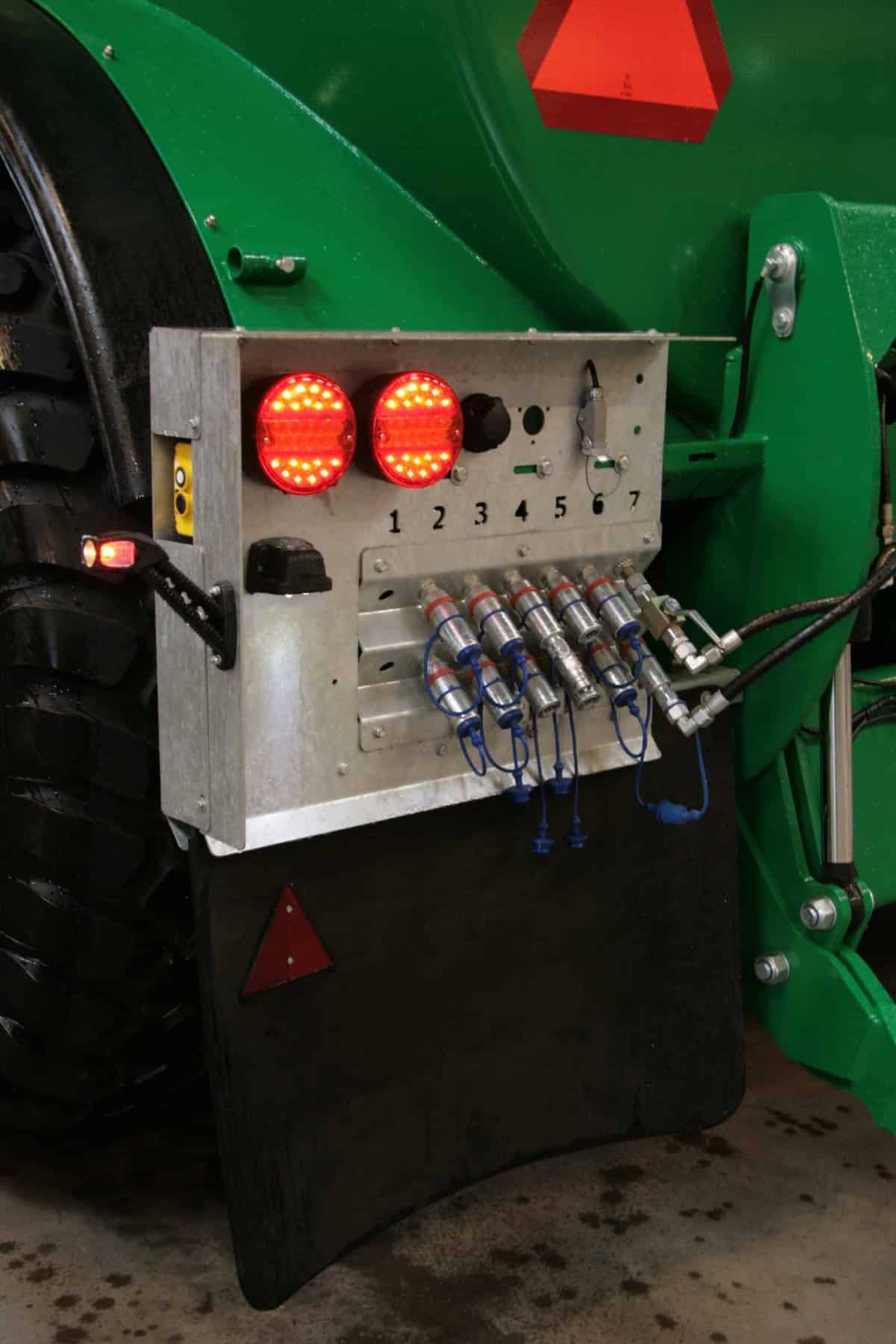

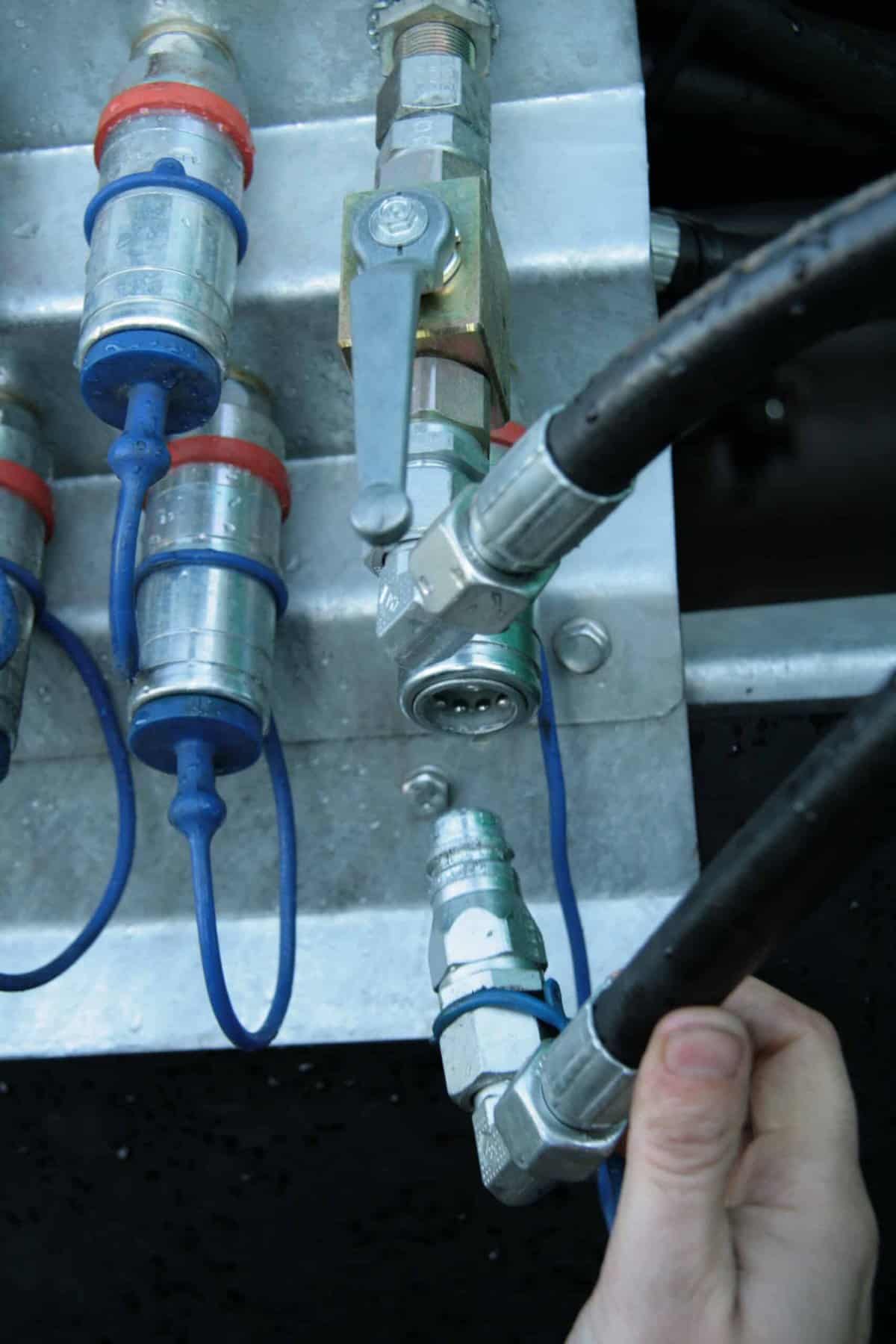

Push/pull quick couplings for the hydraulics between trolley and attachment, numbered "push/pull" type

Quickly switch from one equipment type to another

Flexible pump tower that is easily inserted into slurry tank cover openings

High loading capacity on pump tower

With pump tower, SAP or FAP loading systems, the driver can stay in the cabin during filling

Efficient filling solutions

Via pump tower

Via filling pump with hose on the side

Via SAP arm - one or two-link

Via FAP front arm filling system

Efficient inline ejector suction and loading pump

Large capacity

Can pump even difficult, viscous and inhomogeneous liquids

Does not lose effect over time due to wear and tear

Efficient inline ejector suction and loading pump

The pump is ready to use right away

Handles a wide range of fluid types - fewer operational stops

Not sensitive to foreign bodies in the slurry

Safety and security

Specially designed BPW axles

More powerful brakes 410x180mm

Electronic wheel steering

Hydraulic support leg

LED lights

Rotating beacon and LED work light on rear end

Optimal slurry application - optimal yield

The centrifugal pump ensures very precise and reliable dosing in the application equipment (across the full width of the equipment)

The trailer is lightweight for its size, minimizing damage to fields and plants

The tank is built in sections, with the rear end emptied first. This ensures high weight transfer to the tractor and minimizes the risk of wheel slip and field damage

Due to the high loading and unloading capacity, the likelihood of being able to apply the slurry and nutrients in a timely manner when it is best for the crops and weather conditions are optimal is increased.

Low energy consumption (diesel)

Tank weight is low despite its size

Less traction is needed as the trolley is unloaded from the rear first and is easy to pull due to the large wheels

Efficient centrifugal pump for unloading

Low maintenance costs

The centrifugal pump uses standard components and SAMSON spare parts are readily available

The unloading pipe is galvanized and bolted to the cart

SAMSON manufactures slurry trailers and manure spreaders for maximum application efficiency and the best possible utilization of nutrients in manure.

We supply a wide range of natural fertilizer machines,

-tools and application techniques that incorporate all elements of the fertilization process. Our goal is to

Meet the agricultural industry’s demand for innovative, high-quality, environmentally friendly solutions for the application of natural fertilizers.

Monday – Thursday:

07.00 – 16.00

Friday

07.00 – 15.00

Petersmindevej 6, DK-8800 Viborg

VAT no. 10963230

Copyright © 2024 Samson Agrolize