The FLEX II series is the result of SAMSON’s continued commitment to improve and innovate in agricultural equipment. Building on the success of the well-known FLEX series, FLEX II offers a number of improvements and new options for even more precise application of fertilizer and other materials.

Like its predecessor, the FLEX II series is characterized by its strength, robustness and impressive efficiency. However, FLEX II goes one step further by introducing a number of new features that raise the bar for what a spreader series can achieve.

Flexibility is still a keyword with the FLEX II series. The spreader can be equipped with either vertical or horizontal rollers with a spreading table, allowing the professional user to drive in a wide range of materials and ensure a consistent and precise application in all conditions.

But the FLEX II series doesn’t stop there. With advanced technology and enhanced features, it sets new standards for precision and control. An updated control system gives the user even more control over the spreading process, while advanced sensors ensure accurate dosing and distribution of the material.

MuckControl is an advanced electronic control that regulates the bottom chain of the spreader. This feature ensures uniform and precise spreading of fertilizer or other materials by controlling the speed and movement of the bottom chain.

SpreadMaster 6500 is an electronic control system designed to optimize the spreading process. With drive dependency, this advanced control can adapt the spreading pattern based on vehicle speed and position, ensuring uniform coverage of the field.

The SpreadMaster 6500 offers a range of advanced features, including control of hydraulic functions and volumetric dosing. An intuitive 4.3″ touchscreen provides easy access to all key functions while the system continuously monitors load, area, time and quantity for optimal control and efficiency.

SpreadMaster 8500 is the next generation of electronic control, providing even more advanced control over the spreading process. This controller can be operated both via buttons and touchscreen and has advanced features like dynamic weighing and field map/dosing map upload to optimize dosing based on specific needs and soil conditions.

SpreadMaster 8500 is ISOBUS compatible, which means that it can be integrated with the tractor terminal if it is also ISOBUS compatible. This provides simple operation and integration of the spreader control with other agricultural equipment, increasing flexibility and efficiency in the field.

MuckControl is an advanced electronic control that regulates the bottom chain of the spreader. This feature ensures uniform and precise spreading of fertilizer or other materials by controlling the speed and movement of the bottom chain.

SpreadMaster 6500 is an electronic control system designed to optimize the spreading process. With drive dependency, this advanced control can adapt the spreading pattern based on vehicle speed and position, ensuring uniform coverage of the field.

The SpreadMaster 6500 offers a range of advanced features, including control of hydraulic functions and volumetric dosing. An intuitive 4.3″ touchscreen provides easy access to all key functions while the system continuously monitors load, area, time and quantity for optimal control and efficiency.

SpreadMaster 8500 is the next generation of electronic control, providing even more advanced control over the spreading process. This controller can be operated both via buttons and touchscreen and has advanced features like dynamic weighing and field map/dosing map upload to optimize dosing based on specific needs and soil conditions.

SpreadMaster 8500 is ISOBUS compatible, which means that it can be integrated with the tractor terminal if it is also ISOBUS compatible. This provides simple operation and integration of the spreader control with other agricultural equipment, increasing flexibility and efficiency in the field.

FLEX II SERIES

Long lifetime

Box and rollers are made of Domex 600 high tensile steel.

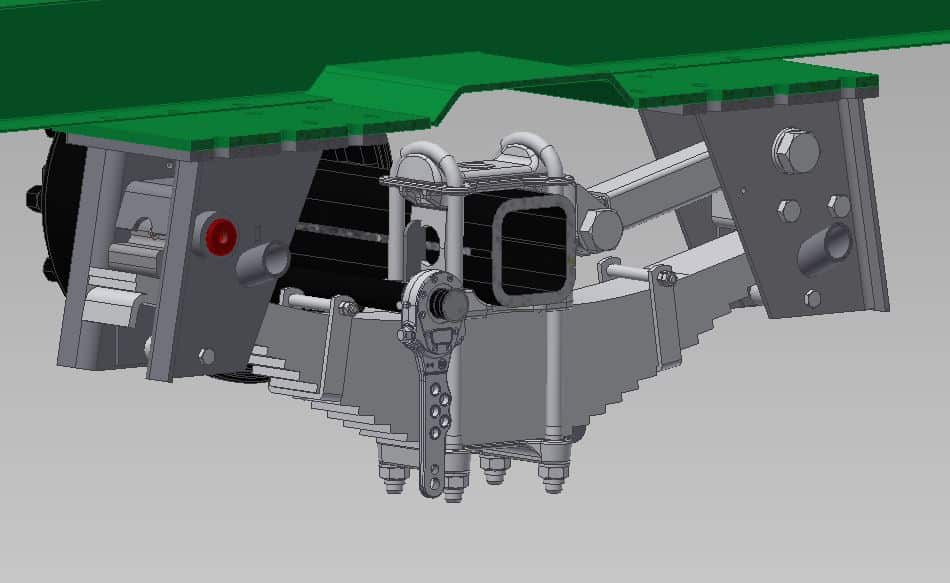

The traction triangle is suspended with maintenance-free shock absorbers.

Each spike on the rollers is made of hardened special steel.

Many SAMSON AGRO spreaders have been running for over 20 years.

The FLEX II spreader is fully welded. There is no spot welding.

4 high-strength bottom chains from Rübig mean less wear on each chain. The tensile strength of each bottom chain is 12.5 tons.

The chain for the rollers on the 24 meter spreader is placed in a closed chain gearbox with oil.

Shock absorption occurs between the rollers and gearbox.

High efficiency

The position and angle of the spreading rollers, the speed of rotation of the spreading rollers (534 rpm), the size of the blades, revolutions and position of the ejectors on the spreading table ensure that the machine can spread the material very quickly. This means more daily loads per machine.

The very low construction ensures a low center of gravity, low loading height and high stability of the machine. This makes it possible to drive faster on roads and in fields. It also means more daily loads per machine.

Optimal nutrient utilization - optimal yield

The design of the spreader and shredder section ensures that the material is pulverized and spread evenly/homogeneously.

It is possible to choose between 12m and 24m spreading equipment depending on the material to be spread. If you mainly spread heavy materials, such as deep litter, you should choose a 12m spreader. If it's mainly lighter materials, such as compost and chicken manure, you should choose 24 m spreading equipment.

Low energy consumption (diesel)

The body is made of Domex 600 steel, which reduces the total weight of the trailer, so the tractor needs less horsepower.

The box is made as a self-supporting construction, eliminating the need for an underlying chassis and reducing the weight of the machine.

The wheels are placed on the side of the machine, ensuring a large diameter and therefore less rolling resistance on the wheels, so the tractor needs less horsepower.

Samson is a leader in the production of spreaders designed to optimize application efficiency and maximize the utilization of nature’s own nutrients.

We offer a comprehensive range of spreaders, tools and technologies, all tailored to meet the needs of the agricultural industry.

Our goal is to provide innovative and environmentally friendly solutions for efficient spreading of organic fertilizers, where every step of the process is carefully thought out. With our spreaders, farmers can make optimal use of resources while contributing to sustainable farming practices.

Monday – Thursday:

07.00 – 16.00

Friday

07.00 – 15.00

Petersmindevej 6, DK-8800 Viborg

VAT no. 10963230

Copyright © 2024 Samson Agrolize